Articles

At Nu Perspectives, we love anything cryogenic, innovative and useful.

We love our industry and we love to talk about it.

Cryogenic consultancy growing in a pandemic – The challenges

Last year was challenging for all of us in many different ways. In a time marred by so much devastation and loss, we wanted to write about something positive. Not to gloat but to share a little hope.

Read more

Emerging cryogenics markets

These are exciting times for the emerging cryogenics markets. It is becoming enormously popular as a treatment choice for many surgeons and cryotherapy proves to be extremely effective in treating cancerous tumours, retinal detachments, treatment of Morton’s neuroma and plantar fasciitis, cardiac surgery and pain relief.

Read more

Expanding our in-house manufacturing and fabrication facilities

At Nu Perspectives we are continuously looking for new ways to improve the service we provide to our clients. We identified a need for expanding our in-house manufacturing facilities which would enable us to manufacture many existing, and new products, that we currently outsource.

Read more

Medtech shortage in cryogenic engineering expertise

In the UK, large scale companies working on industrial cryogenics projects, often have their own in-house expertise. In contrast, smaller medical device manufacturers struggle to find trained professionals with precision engineering skill and cryogenic expertise. Because of this, many manufacturers seek specialist cryogenic consultancies to plug the gap.

Read more

Darren’s sight saving cryosurgery

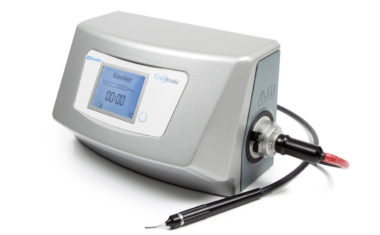

At Nu Perspectives we design, manufacture and test cryoprobes and one such probe is a device we worked alongside Keeler to design and develop.

Read more

The treatment of liver cancer by cryoablation

Some twenty years ago a surgeon called Tim Allen-Mersh, was pioneering a method of freezing cancerous tumours with liquid nitrogen. The method involved inserting a probe into a tumour, via a needle and freezing the tip to create an ice ball.

Read more

Dealing with the challenge of coupling design for cryogenics

All engineers working in cryogenics, struggle with the challenge of coupling design. It’s important not to waste liquid nitrogen while keeping the liquid cold enough to work quickly. That’s why Nu Perspectives set about creating a brand new coupling design.

Read more