Case Studies

If you’d like a more detailed view of the types of cryogenic design and engineering projects that we undertake, then please take a look at our case studies and product profiles.

We have highlighted particular projects, and products, that we thought would be of most interest.

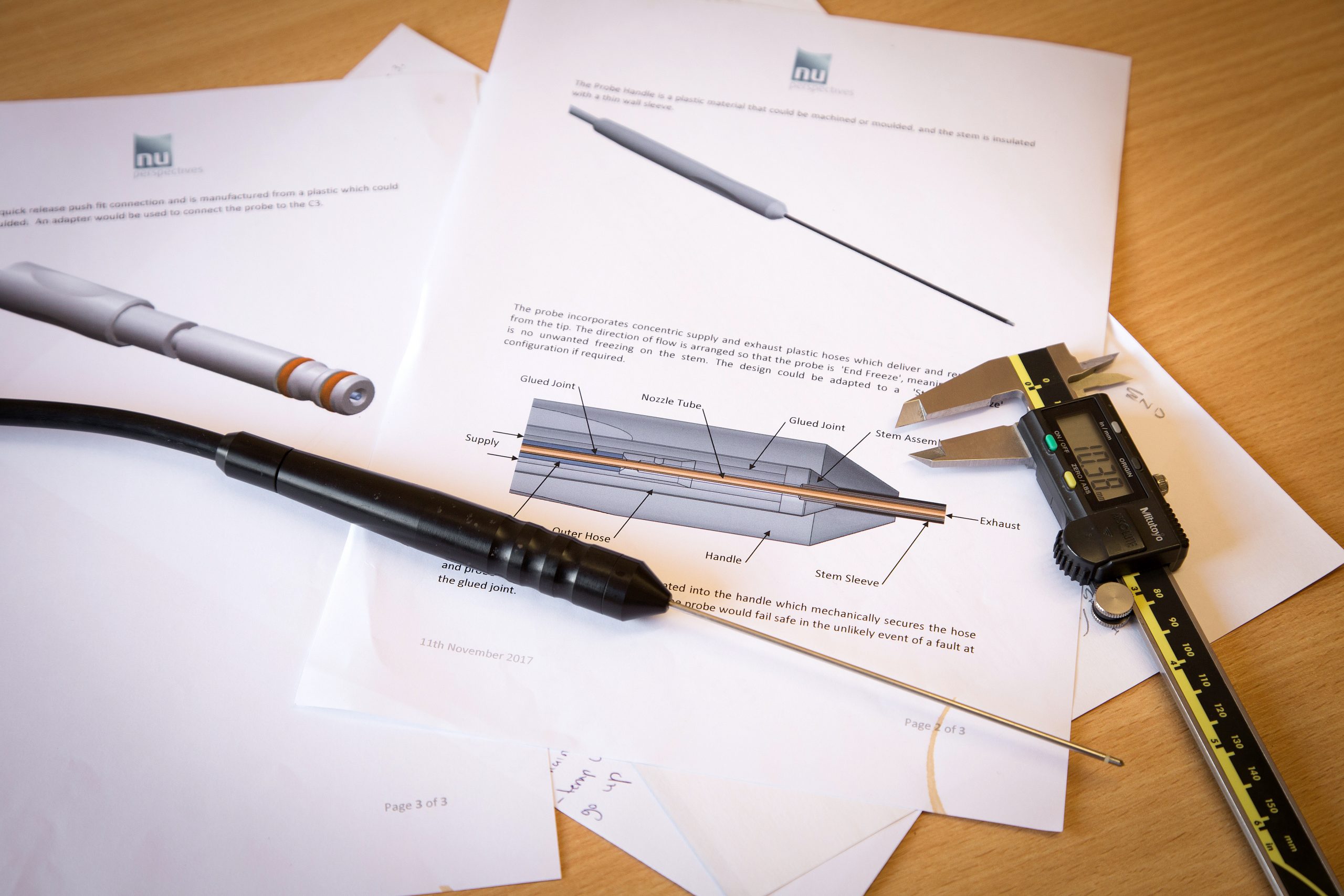

Bespoke cryogenic instruments for probe stem assembly

At Nu Perspectives we pride ourselves on finding bespoke solutions to cryogenic system problems, in-house. We are constantly looking for ways to improve our processes.

Find out moreCryogenic concepts for specialised pain management

We were approached to design and develop a new medical device, for cryotherapy and pain management. It involved combining nerve stimulation and cryotherapeutic technologies within a single revolutionary medical device.

Find out moreDesign and manufacture of modular pneumatic control systems

Nu Perspectives is experienced in the design and manufacture of modular control systems, for various pneumatic applications, with pressures ranging from a few PSI to over 100 bar.

Find out moreIn-house testing and repair for legacy cryogenic surgical product

At Nu Perspectives we have our own in-house testing and manufacturing facility, which means we are able to carry out tests and repairs on products directly ourselves, even if they are legacy systems.

Find out morePrecision manufacturing of cryosurgical probe stems

Nu Perspectives specialises in the design and manufacture of cryosurgical probe tips for clinical applications, ranging from ophthalmology to pain management. These products develop extremely low temperatures at the tip, via the circulation of high pressure cryogenic gases.

Find out moreReducing costs to produce a new probe coupling mechanism

We were approached by a client who was working with a leading ophthalmic cryosurgical system. They wanted us to develop an intuitive, easy to operate mechanism, for connecting and disconnecting a range of reusable and disposable cryosurgical probes, to and from the control console.

Find out moreReverse engineering to create a new part for legacy cryosurgery probe

At Nu Perspectives we pride ourselves on having in-house manufacturing capability. This came to the fore, when a client approached us to supply a spare part for a legacy cryosurgery probe.

Find out moreService and repair of legacy cryosurgical devices

Cryosurgical devices are subjected to extremes of temperature and internal pressures, when in use and during routine sterilisation and cleaning. Internal components are prone to wear and tear and require replacement periodically.

Find out moreSpecifying correct orifice sizes for gas based cryosurgical probes

Gas based cryosurgical probes use the Joule-Thomson (JT) effect to achieve rapid freezing at the probe tip. The JT effect is a thermodynamic process that occurs when high pressure gas is flowed through a small orifice into a large chamber, causing a pressure drop.

Find out more